ABOUT US

- DE.MA S.r.l. was founded in 1995 by brothers Corrado and Massimo Mauri

- It is a fully equipped company that produces and builds with its own skilled workers

- it is a company that can operate directly in Italy or abroad

- it is a company that invests today, because it believes in tomorrow

OUR SKILLS

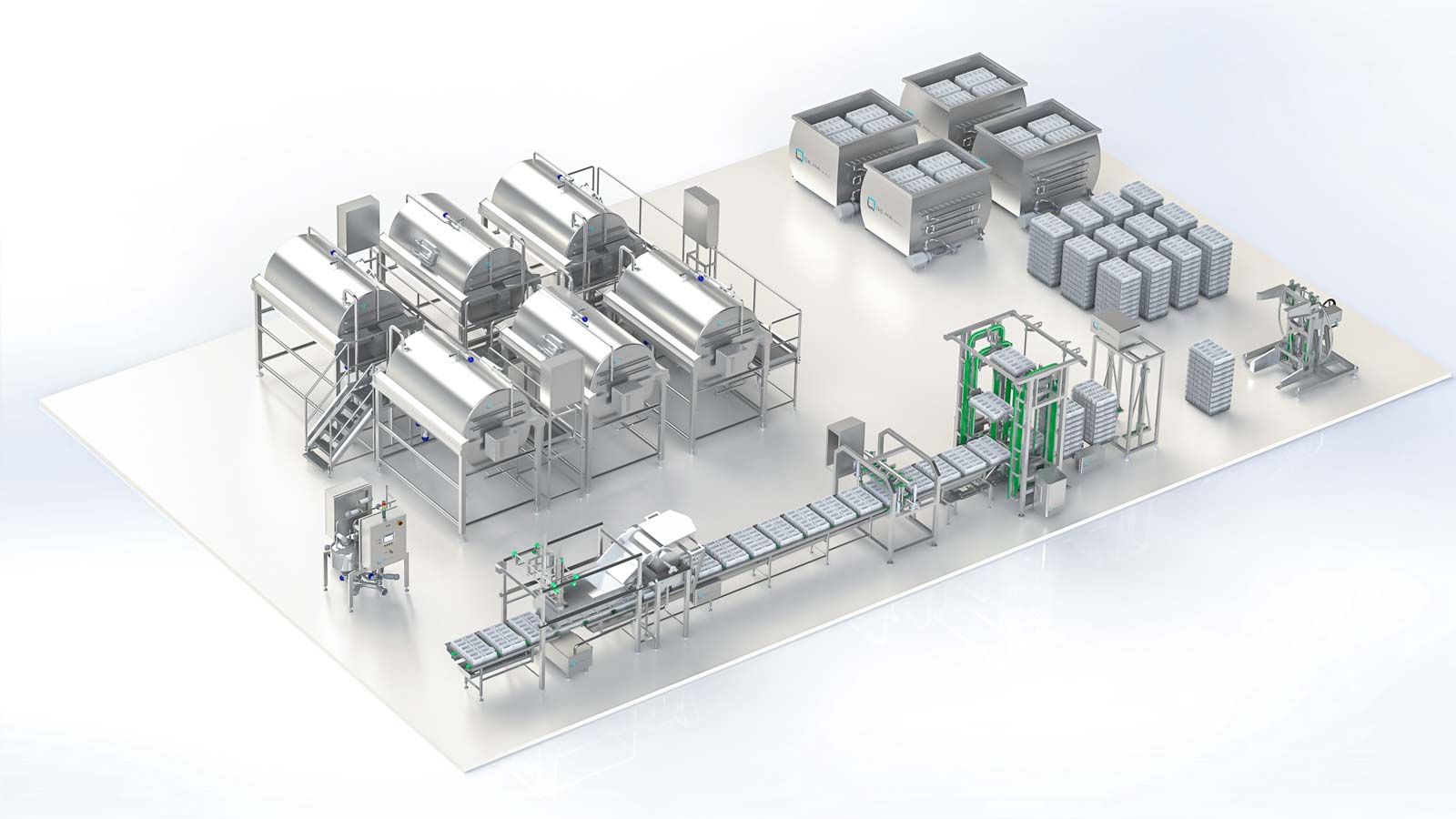

DE.MA S.r.l., thanks to a team boasting more than thirty years’ experience, designs and develops turnkey systems for the dairy and food sectors. De.Ma S.r.l. looks after the design and development of systems for:

– Processing of raw materials, intended as receiving, storage, cooling, skimming, pasteurisation and cip systems;

– Transformation, production, and distribution in various production environments, intended as coagulation platforms, forming lines, handling lines for hot and cold maturation chambers.

De.Ma S.r.l. carries out the above from its own headquarters complete with administrative offices, a technical and production department.

PRODUCTS & SERVICES FOR FOOD SECTOR:

– Milk processing and standardisation;

– User CIP systems;

– Soft and fresh cheeses;

– Blue cheeses;

– Curd maturation for stretch-curd cheeses;

– Semi-hard cheeses

– Batched or continuous ricotta;

– Mascarpone and spreadable cheeses;

– Filling lines for ice creams and frozen desserts;

– Volumetric dosing stations;

– Variegators for decorations.

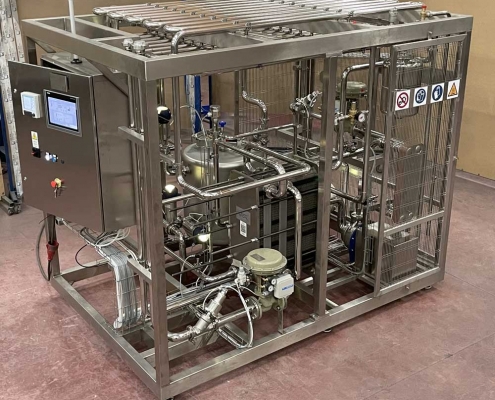

REVAMPING:

– Machines for the production of fresh products;

– Processing systems;

– Piping;

– Mechanical tools;

– Automations.