In 2023, DE.MA Srl purchased the new Trumpf press brake, TRUBEND 5320.

Machine Description:

- The machine’s sturdy frame consists of a welded structure, which in turn consists of a press table, 2 side columns and connecting beams

- The entire machine design was calculated using the finite element method and was designed to resist fatigue

- The robust frame design ensures precise results even after years of continuous operation under maximum loads

Press beam

- The press beam is characterised by high rigidity, thus ensuring precise bending results

- The press beam is guided by double roller bearings on both sides

- Z-direction guide rollers stabilise the press beam and prevent radial forces on the cylinder seals

- High and constant bending accuracy is achieved through hardened bars and the adjustable “zero-play” setting

Press beam spherical bearing in tilted position

- Spherical joint between press beam and cylinder

- The tilting function allows the production of geometric shapes such as funnels, and allows simple corrections during the production of long profiles

- The spherical bearing prevents damage to the cylinder (leakage) due to radial forces caused by press beam tilting

On-Demand servo drive with 4-cylinder technology

- Very silent and energy-efficient electro-hydraulic drive

- Positioning is regulated by 2 synchronous servo motors that are only actuated during the bending process

- The high axis speeds (rapid down movement, Y-axis return and closing movement) ensure high productivity

- The 4-cylinder technology reduces press beam deflection and thus ensures improved workpiece precision

- The flat design of the 4-cylinder technology increases the bending space in front of the machine

Length (Y-axis) measuring system with dynamic compensation of elastic deformation - The high positioning accuracy of the press beam (Y-axis) is ensured by distance measuring systems

- Despite the sturdy design of the machine frame, elastic deformation cannot be ruled out in the presence of high pressing forces. This elastic deformation is recorded by precision linear encoders and automatically compensated

- Elastic deformation compensation ensures accurate results under various stresses

- Extended open height/stroke:

- 230 mm extension of the effective open heigh for a total of 615 mm

- 230 mm increase of Y stroke for a total of 445 mm

- Significant increase in the diversity of pieces, particularly with regard to possible nesting depths

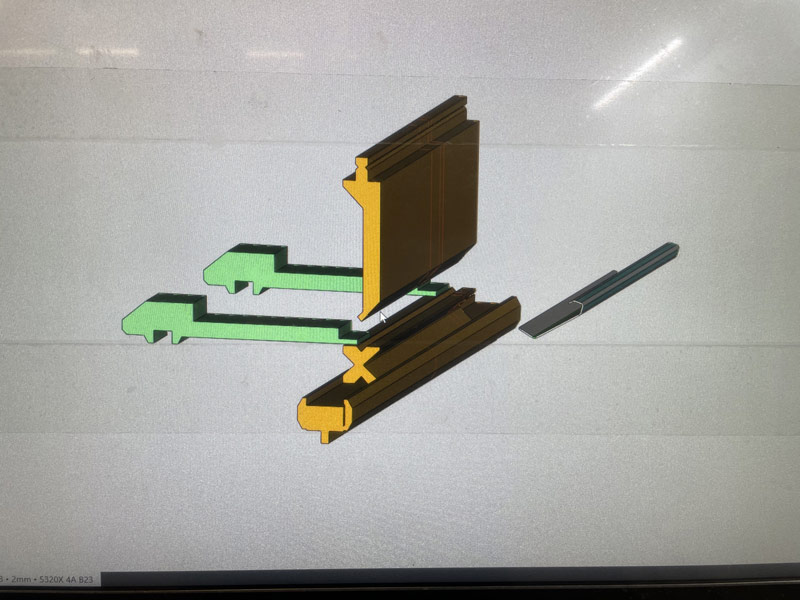

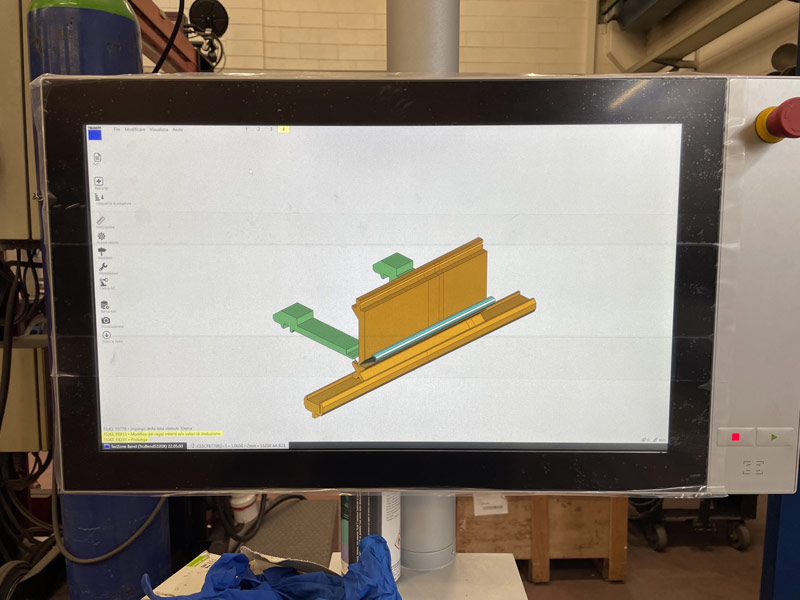

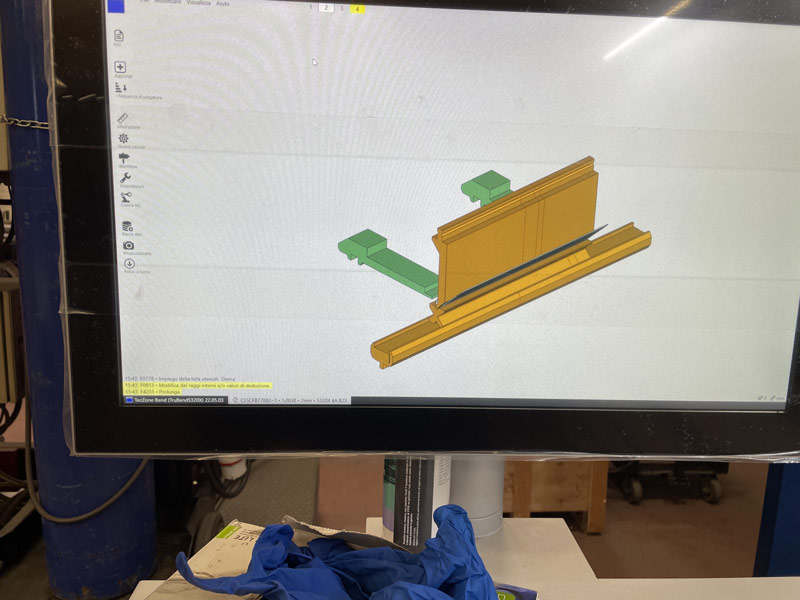

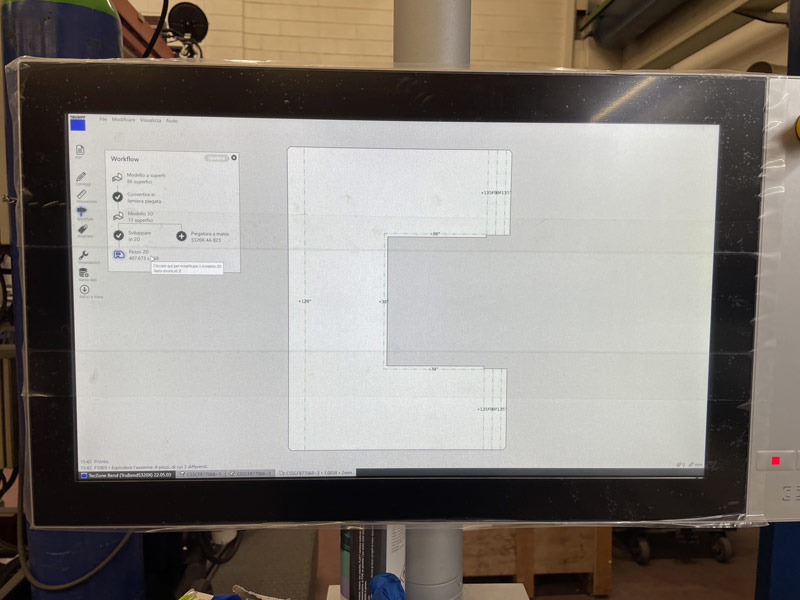

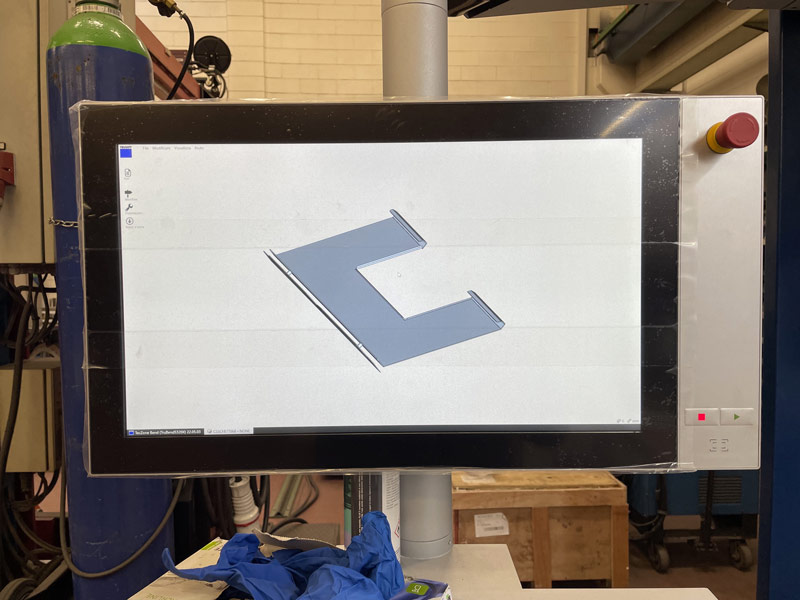

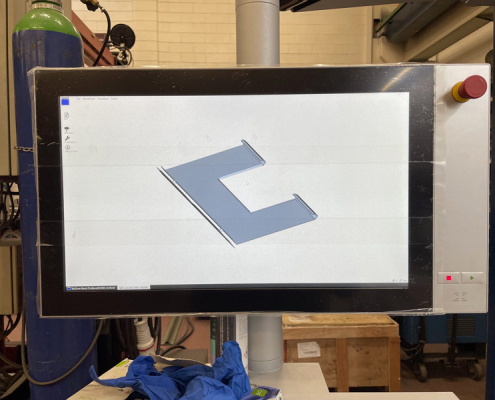

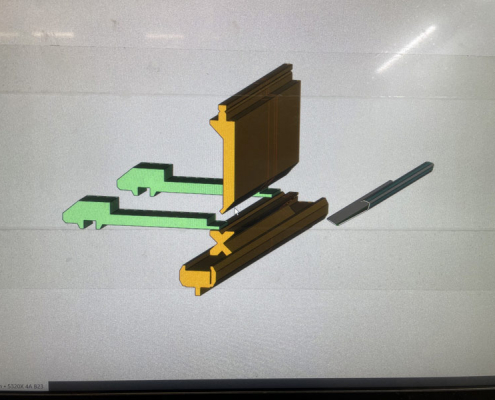

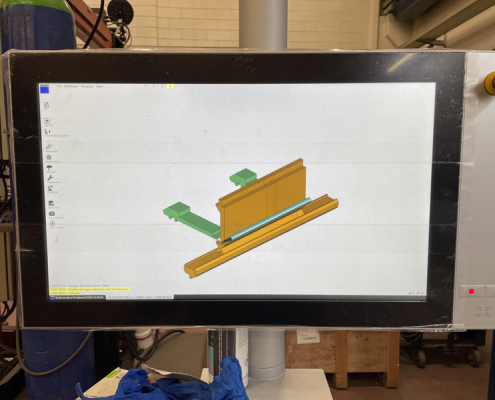

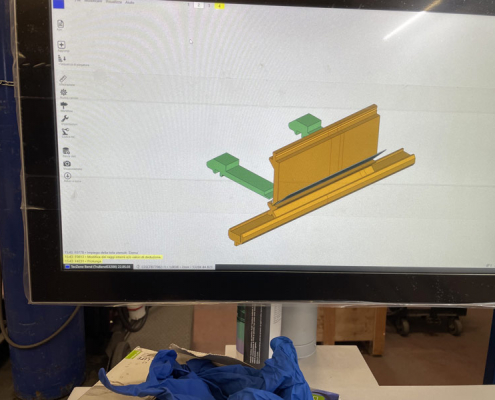

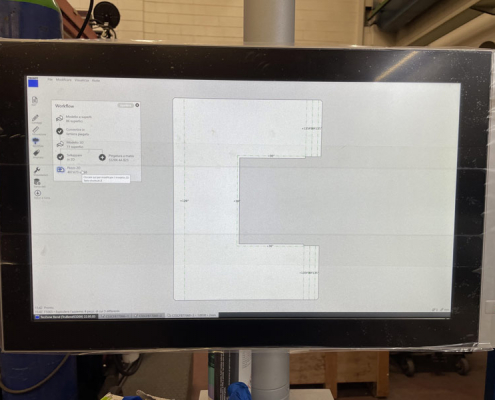

Machine shop programming – TecZoneBend

- Automatic creation of a program proposal based on 2D and 3D data

- Possible manual modification of bending programs

- The programming automatically creates the 3D simulation including collision checks

- Creation of NC program

Technical Data:

- Press force

- Bending length

- Width between columns

- Usable open height

- Press beam tilt

- Outreach

- Table width

- Maximum distance between press table and press beam

- Operating height (min/max) 1

- 3200 kN

- 4420 mm

- 3680 mm

- 615 mm

- ± 10 mm

- 420 mm

- 200 mm

- 735 mm

- 1110 mm- 1130 mm